Loading...

Innovate and Improve

PMA Parts and DER Repair solutions

Repair Technology

Measure Tech has designed repairs that not only fix the problem but also create reliability improvements. In several cases, we have created DER repairs where the part would need to be scrapped if it did not pass the bench test.

Cutting edge technology and listening to our customers play a key role in repair design and operations. To date, these repair programs have created millions in cost reduction for our customers. Can we design a repair for you?

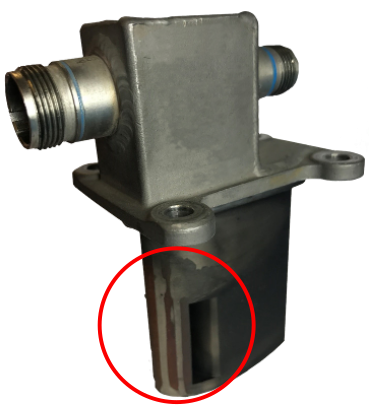

Before

Damamge to the airfoil.

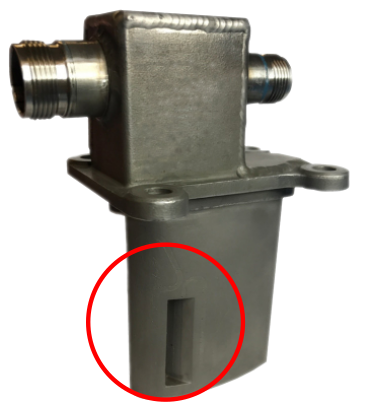

After

Our approved repair process restores measuring accuracy.

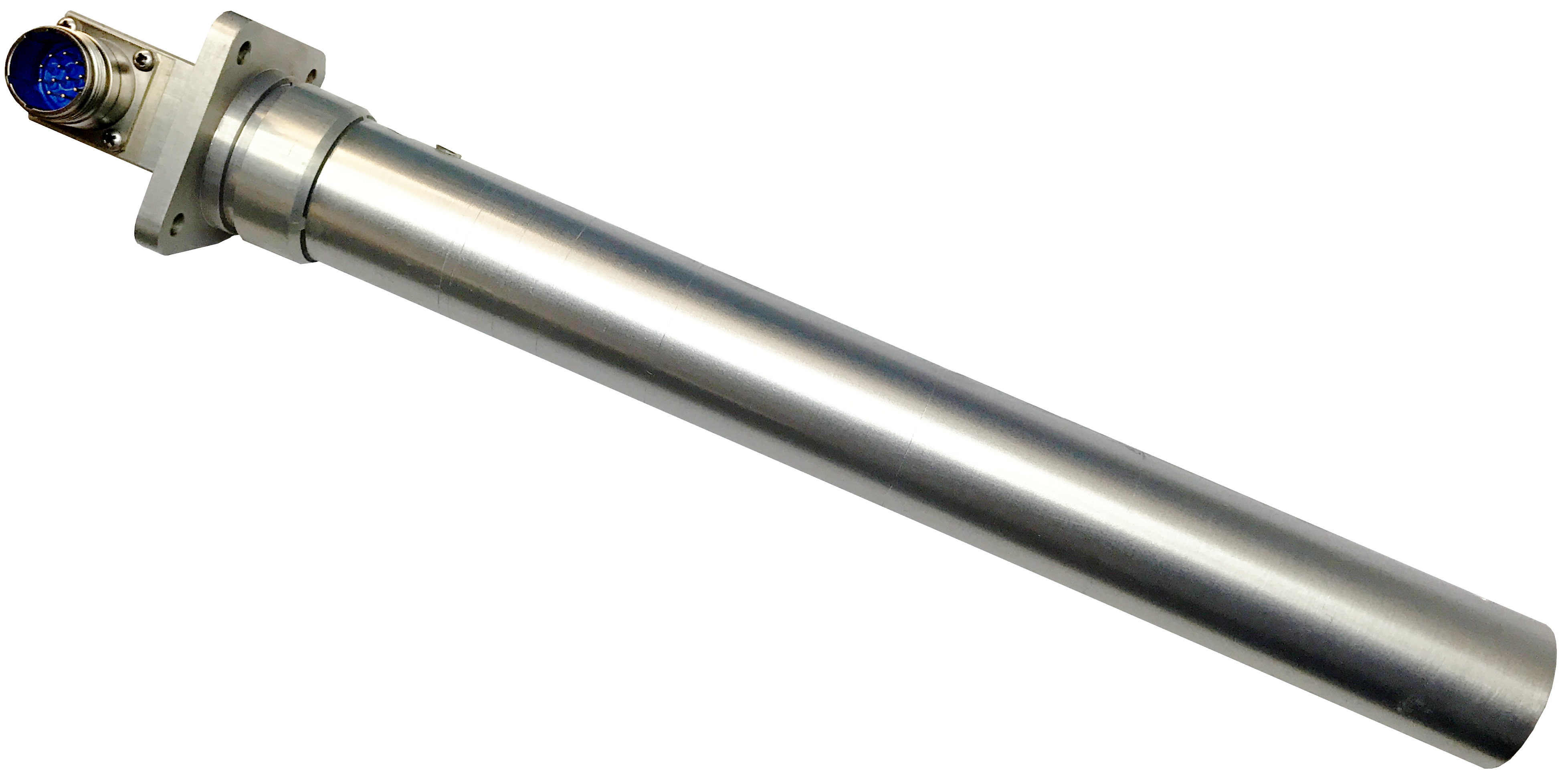

Our CF34-8 Fan Inlet Temperature Sensor RSDER repair includes the ability to re-plate damaged air foils and our

improved design temperature probe provides increased reliability.

Until now, if this sensor failed any

test or inspection parameter; it was beyond economical repair (BER). The Measure Tech repair makes these sensors

operational again at a fraction of the cost of new.This technology can be used on other similar inlet

temperature sensors.

Improvements are also possible utilizing the DER Repair process.

CF34-8B/E Oil Level and Temperature Sensor

Our RSDER repair for the

CF34-8 oil level temperature sensor includes a new Measure Tech design temperature probe (RTD) to prevent oil

ingress at all temperatures as a way to improve reliability.

All facets of the oil level sensing function

can be repaired as well at a flat rate price that is much less than a comparable repair/product improvement from

the OEM.

Your Source for PMA and DER Repairs

© 2018 Measure tech inc.

20650 Bahama Street

Chatsworth CA, 91311

•Phone: (818) 734-9075

•Fax: (818) 734-9087